Step-by-Step Guide to Pultrusion Process: Key Steps and Techniques

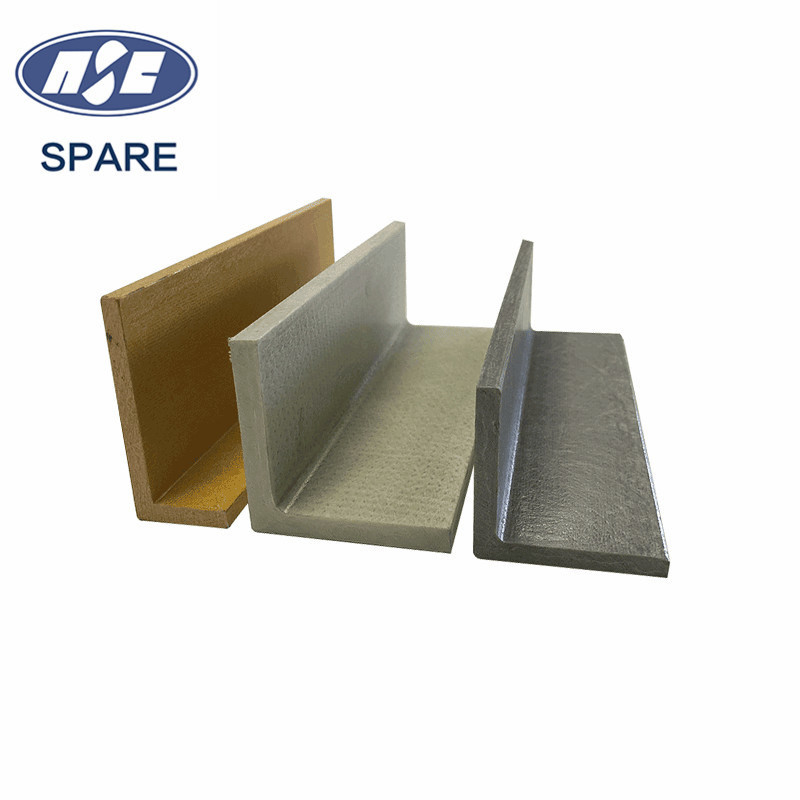

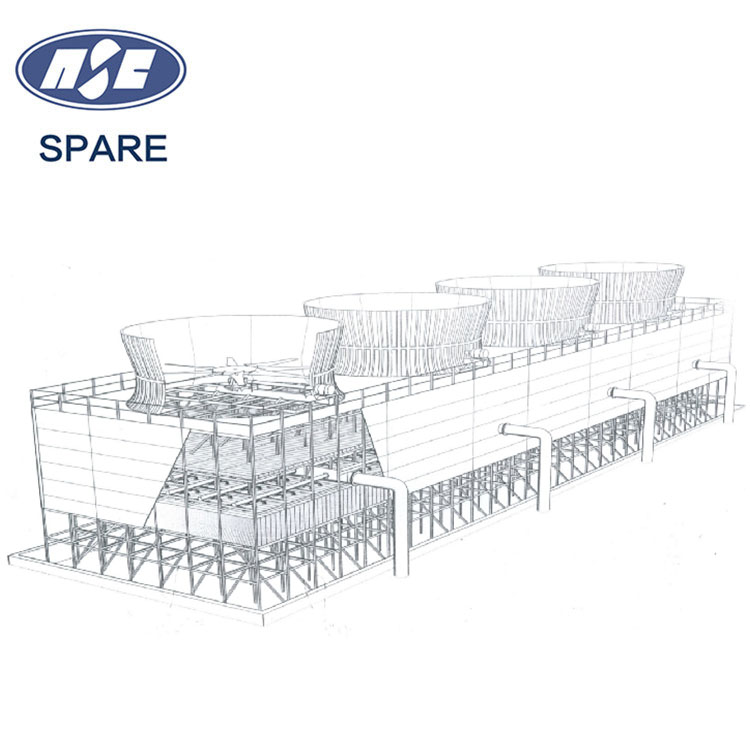

Introducing Nanjing Spare Composites Co., Ltd.'s innovative pultrusion process. Our company specializes in producing high-quality composite materials through a precise and efficient pultrusion process, The pultrusion process is a continuous manufacturing method in which fiber reinforcements are pulled through a resin bath and then into a shaping die, creating a strong and durable composite product. Nanjing Spare Composites Co., Ltd. has mastered this process to produce a wide range of composite materials, including rods, tubes, and profiles for various applications such as construction, automotive, and infrastructure, Our pultrusion process involves several key steps, including raw material selection, fiber pre-treatment, resin impregnation, curing, and cutting. Through strict quality control measures, we ensure that our products meet the highest industry standards for strength, durability, and performance, At Nanjing Spare Composites Co., Ltd., we are committed to providing our customers with top-quality composite materials that are tailored to their specific needs. With our advanced pultrusion process, we can deliver reliable and cost-effective solutions for a wide range of industries. Contact us today to learn more about our pultrusion process and discuss your composite material needs