Pultrusion Manufacturing Process: Advantages and Applications

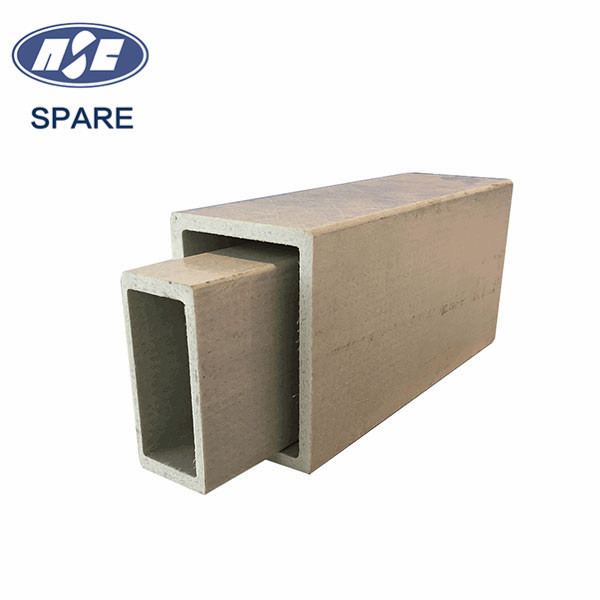

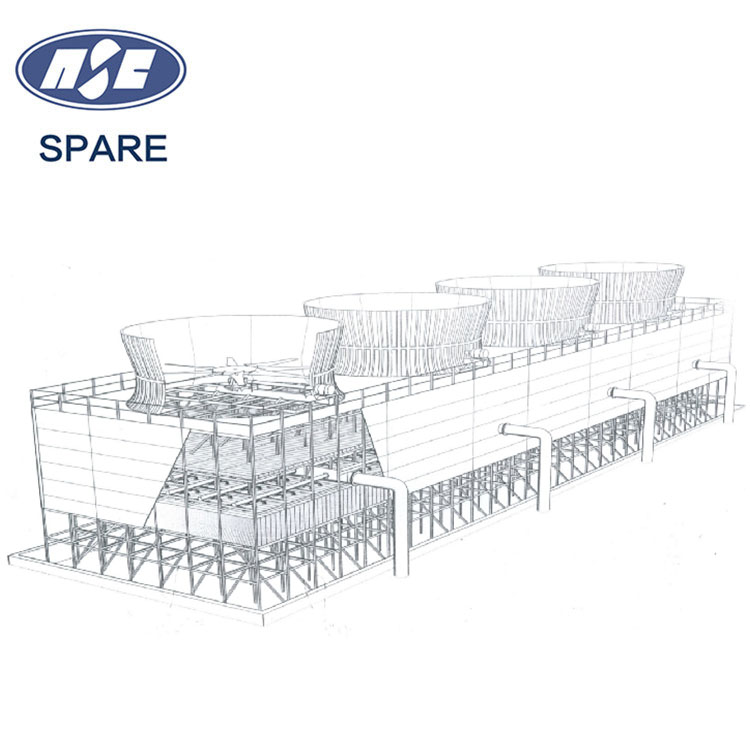

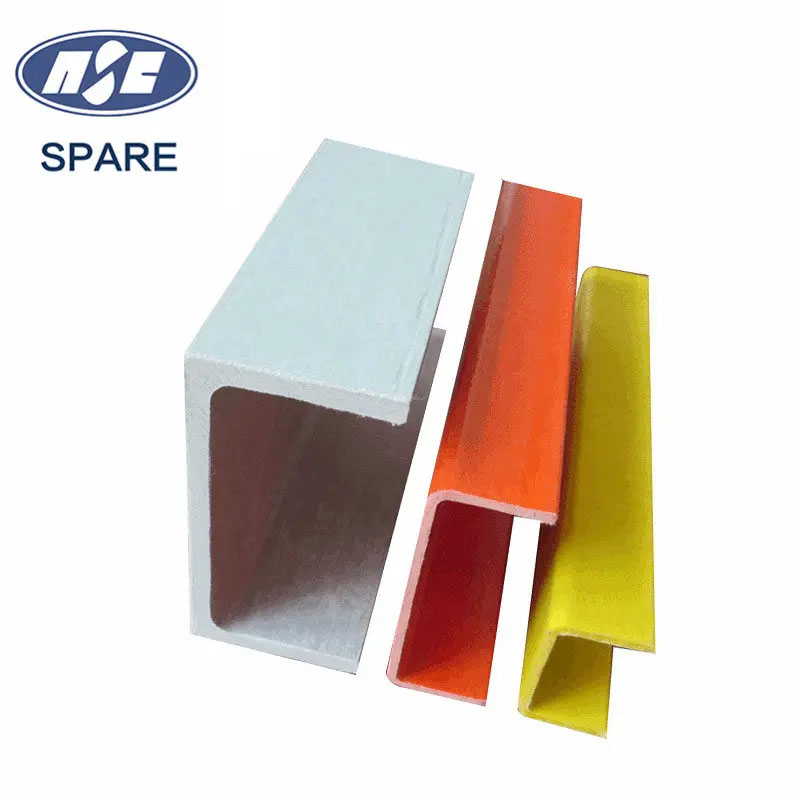

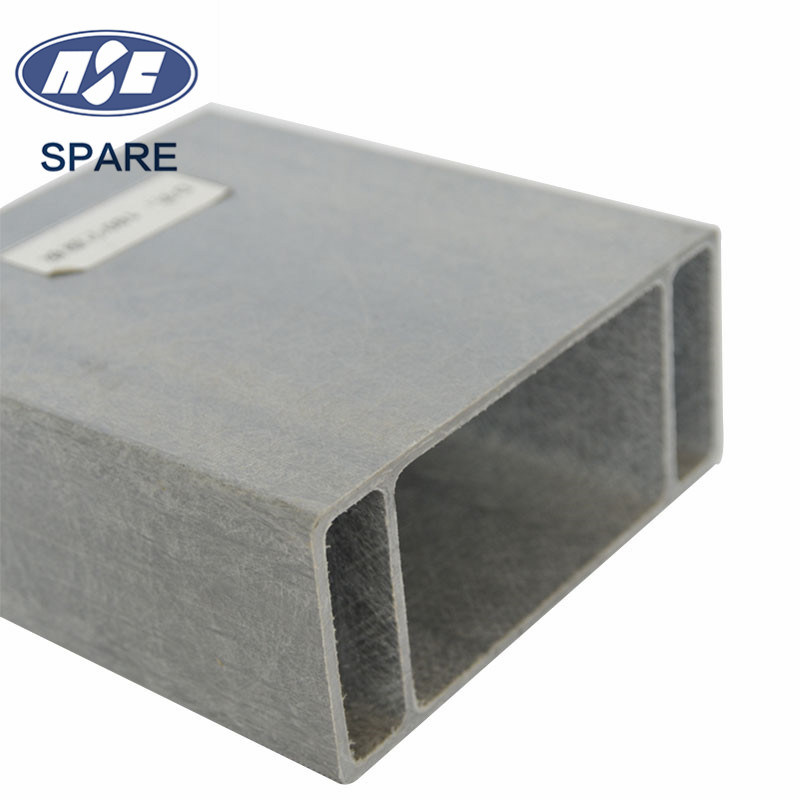

Introducing Nanjing Spare Composites Co., Ltd.'s cutting-edge products manufactured using the Pultrusion Manufacturing Process. Our company specializes in producing high-quality composite materials using this innovative technique, resulting in products that are incredibly durable, lightweight, and versatile, Pultrusion is a continuous manufacturing process that produces reinforced plastic products with constant cross-sections. This process allows for the production of various composite materials such as fiberglass, carbon fiber, and other reinforcements, offering exceptional strength, stiffness, and corrosion resistance, At Nanjing Spare Composites Co., Ltd., we utilize the Pultrusion Manufacturing Process to create a wide range of products including rods, tubes, profiles, and custom-designed parts for a variety of industries such as construction, infrastructure, automotive, aerospace, and more. Our products are known for their superior performance, longevity, and reliability, making them the ideal choice for demanding applications, With a commitment to quality and innovation, Nanjing Spare Composites Co., Ltd. is your trusted partner for high-performance composite solutions manufactured through the Pultrusion process. Contact us today to learn more about our products and how they can meet your specific needs