Pultrusion Advantages and Disadvantages: A Comprehensive Guide

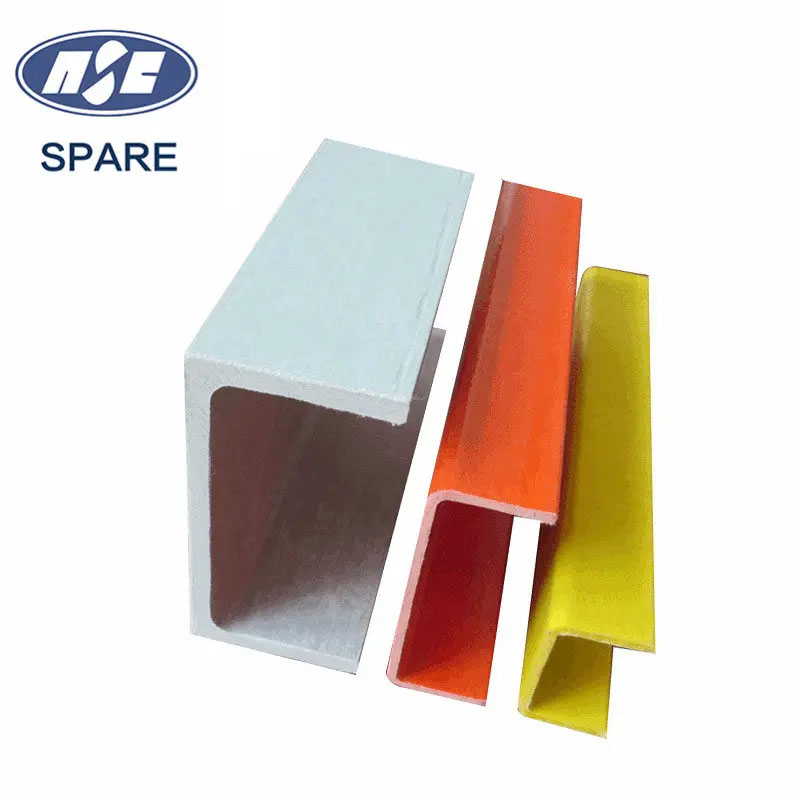

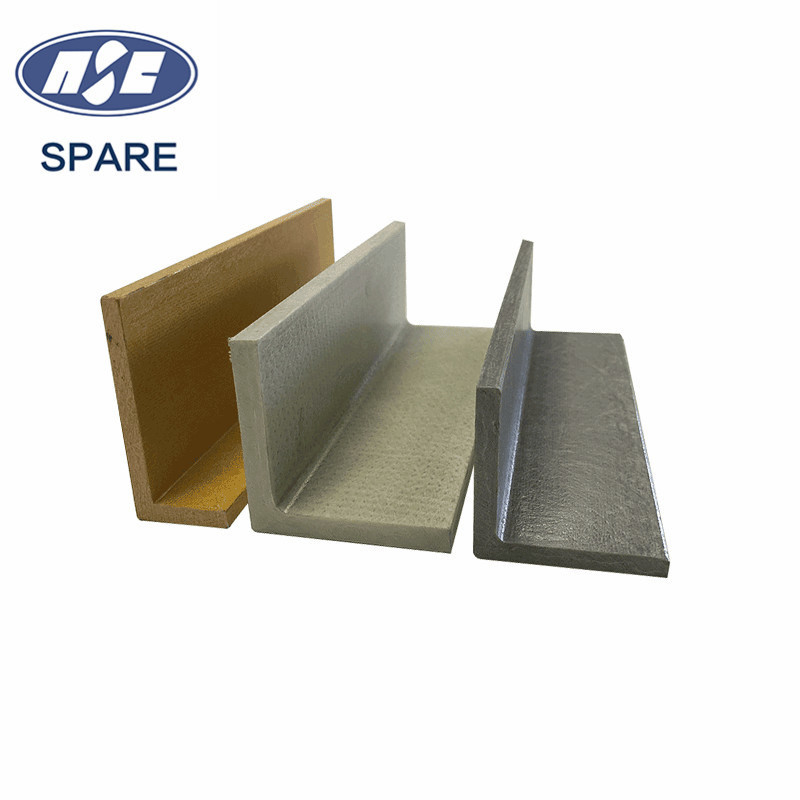

Spare Composites Co., Ltd. is proud to introduce our latest innovative product utilizing pultrusion technology. Pultrusion offers various advantages, making it an ideal method for manufacturing high-performance composite products, One of the major advantages of pultrusion is its ability to produce continuous, uniform cross-sections with high strength and stiffness. This results in lightweight yet durable products that are resistant to corrosion, chemicals, and extreme temperatures. Additionally, pultrusion allows for the integration of various reinforcement materials, such as fiberglass and carbon fiber, to enhance the mechanical properties of the composites, Moreover, pultruded products have excellent dimensional stability and can be tailored to specific design requirements with minimal waste. This efficient manufacturing process also offers cost savings and reduces production lead times compared to traditional methods, However, it is important to note that pultrusion may have limitations in producing complex shapes and may require high initial investment in specialized equipment. Our team at Spare Composites Co., Ltd. is committed to leveraging the advantages of pultrusion technology to provide custom, high-quality composite solutions for various industries