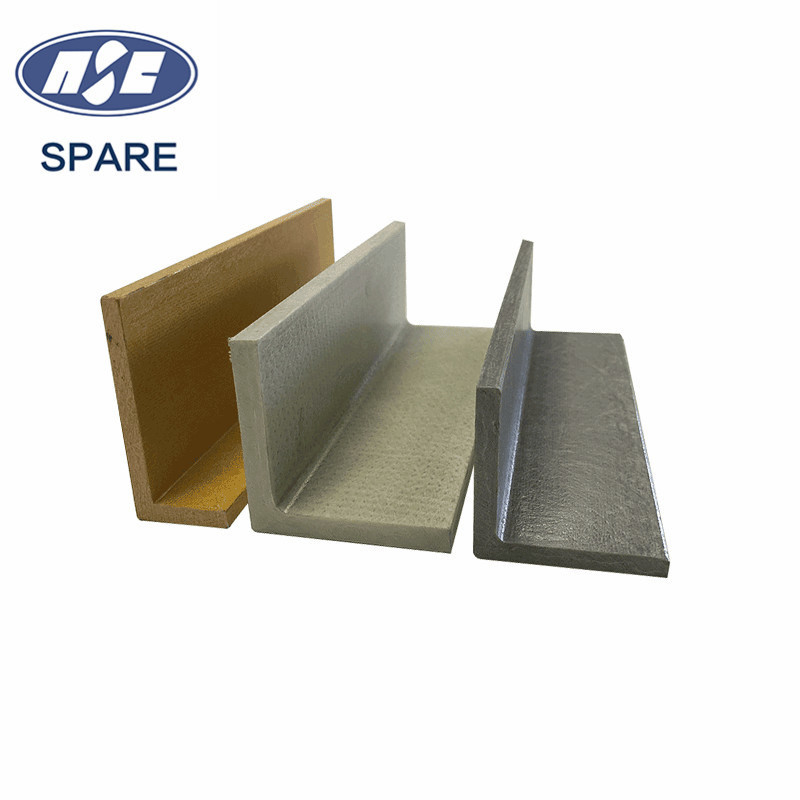

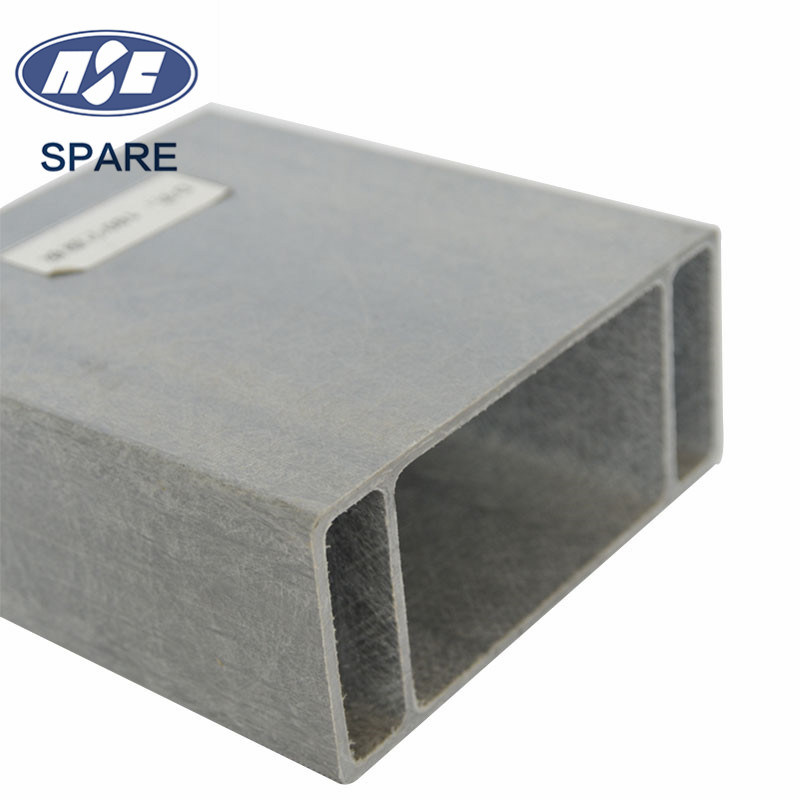

Pultrusion Process: Explained and Simplified for Better Understanding

Spare Composites Co., Ltd. is proud to introduce our latest product utilizing the pultrusion process, a manufacturing method we specialize in. Pultrusion is a continuous process for manufacturing composite materials with a constant cross-section, such as beams, rods, and tubes. This process involves pulling reinforcing fibers through a resin bath before forming and curing the material in a heated die. The result is a high-strength, lightweight composite product that is ideal for a wide range of applications, from construction and infrastructure to aerospace and automotive industries, Our company, Nanjing Spare Composites Co., Ltd., has perfected the pultrusion process to produce top-quality, customizable composite products that meet the specific needs of our customers. With our state-of-the-art facilities and experienced team, we are committed to delivering durable, high-performance solutions for your projects, Whether you need custom-made pultruded profiles or standard shapes, Nanjing Spare Composites Co., Ltd. has the capability and expertise to meet your requirements. Contact us today to learn more about how our pultruded products can enhance the performance and efficiency of your next project