Difference Between FRP and GRP: Key Distinctions and Applications

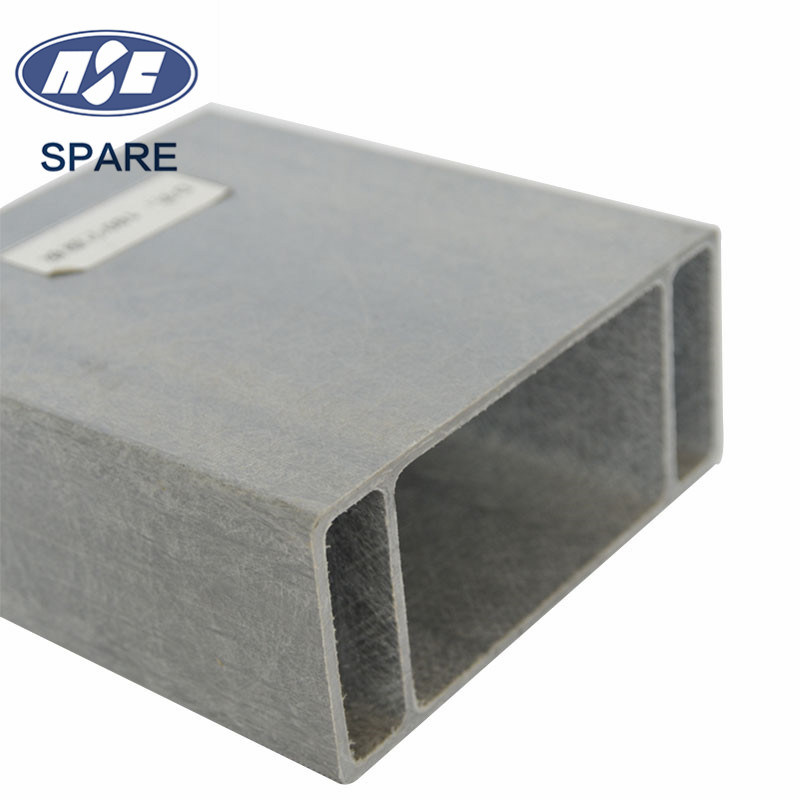

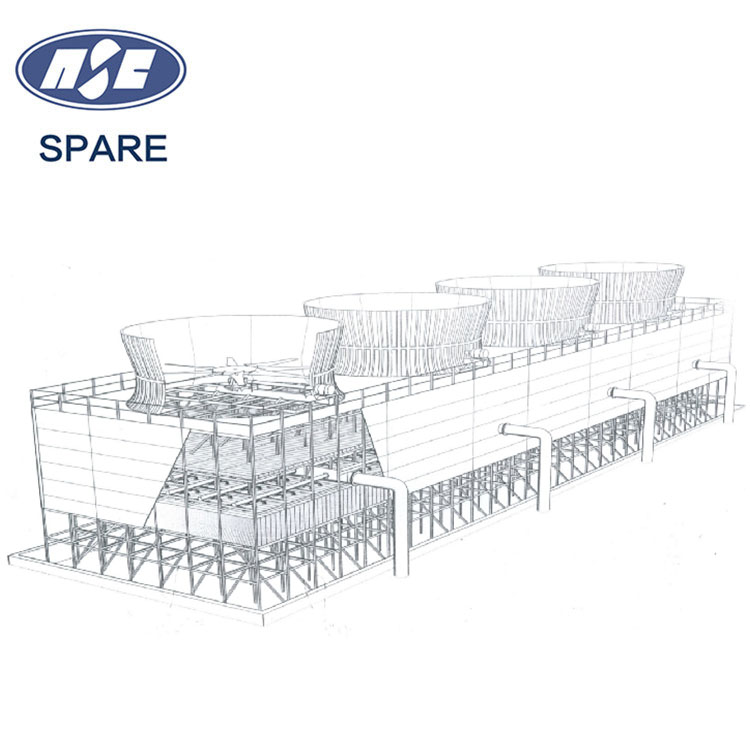

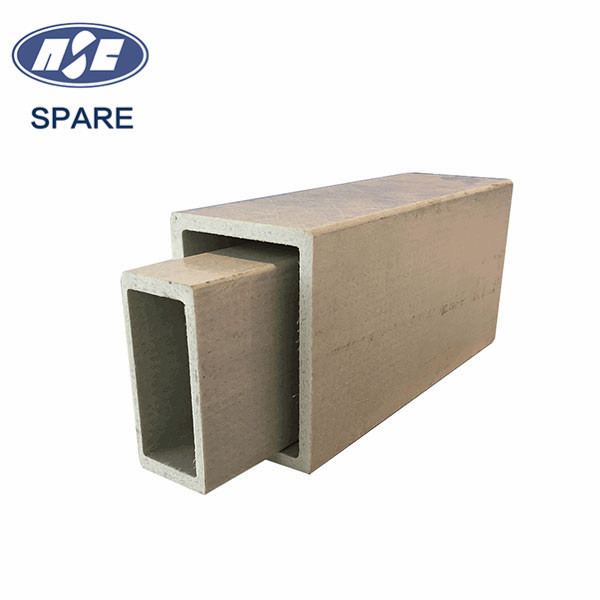

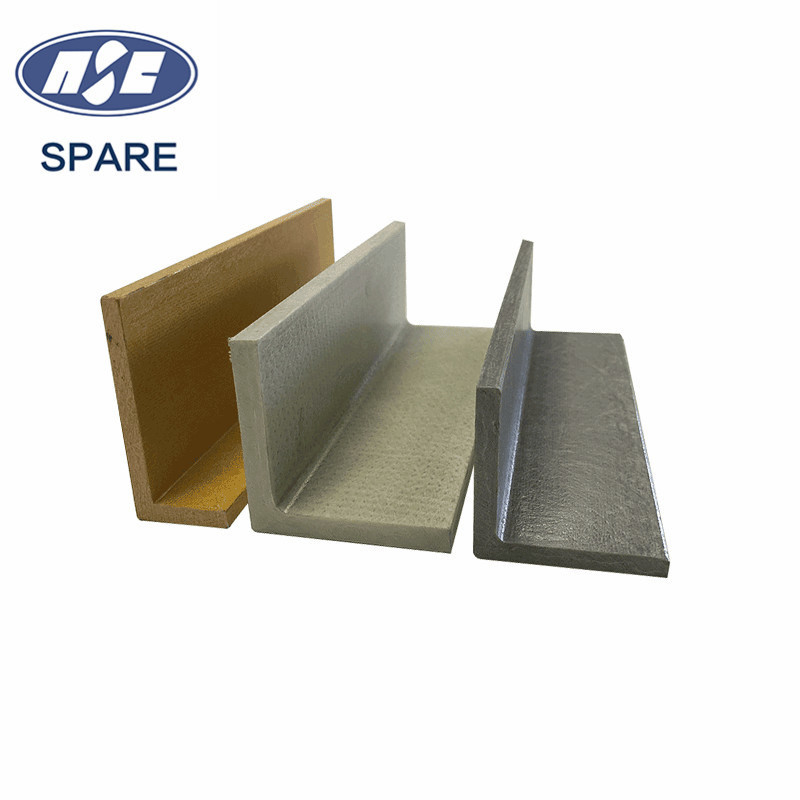

Nanjing Spare Composites Co., Ltd. is proud to introduce our range of composite products, including FRP (Fiber Reinforced Plastic) and GRP (Glass Reinforced Plastic). Both materials offer excellent strength-to-weight ratios, corrosion resistance, and design flexibility, making them ideal for a wide range of applications, The main difference between FRP and GRP lies in the reinforcement material used. While both materials use a polymer matrix, FRP uses fibers such as carbon, aramid, or glass for reinforcement, whereas GRP specifically uses glass fibers. This difference in reinforcement material can result in variations in mechanical properties, thermal stability, and cost, Our FRP products are well-suited for applications that require high strength and stiffness, such as automotive components, aerospace parts, and construction materials. On the other hand, our GRP products are ideal for applications where corrosion resistance and electrical insulation are key requirements, such as chemical tanks, pipes, and electrical enclosures, At Nanjing Spare Composites Co., Ltd., we are committed to providing high-quality composite products that meet the specific needs of our customers. Contact us today to learn more about our FRP and GRP offerings